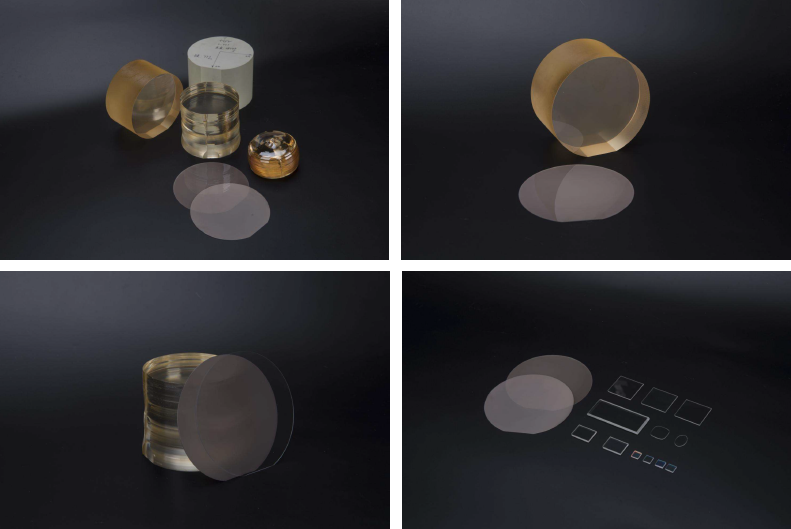

LiNbO3 and LiTaO3 wafer

LN (LiNbO₃) and LT (LiTaO₃) are utilized as substrate materials in piezoelectric devices, surface acoustic wave (SAW) devices, and laser devices, taking advantage of their piezoelectricity, pyroelectricity, and nonlinear optical effects.

We have Optical grade, SAW grade, and Black wafer for LN and LT respectively. Doped wafers are available: Fe/Zn/MgO/Er.

For inquiry, please give us the following information:

- Material

- Size (Diameter / Thickness)

- Polishing Side (SSP or DSP )

- Doping

- Quantity

Specifications

LiNbO3

| Material | Optical grade LiNbO3 wafers | |

| Curie Temp | 1142±2.0℃ | |

| Cutting Angle | X/Y/Z etc | |

| Diameter/size | 2”/3”/4” | |

| Tol(±) | <0.20 mm | |

| Thickness | 0.18 ~ 0.5mm or more | |

| Primary Flat | 16mm/22mm /32mm | |

| TTV | <3µm | |

| Bow | -30<bow<30 | |

| Warp | <40µm | |

| Orientation Flat | All available | |

| Surface Type | Single Side Polished /Double Sides Polished | |

| Polished side Ra | <0.5nm | |

| S/D | 20/10 | |

| Edge Criteria | R=0.2mm or Bullnose | |

| Optical doped | Fe/Zn/MgO etc | |

| Wafer Surface Criteria | Refractive index | No=2.2878/Ne=2.2033 @632nm wavelength |

| Contamination, | None | |

| Particles ¢>0.3 µ m | <= 30 | |

| Scratch , Chipping | None | |

| Defect | No edge cracks, scratches, saw marks, stains | |

| Packaging | Qty/Wafer box | 25pcs per box |

| Material | SAW grade LiNbO3 wafers | |

| Curie Temp | 1142±2.0℃ | |

| Cutting Angle | X/Y/Z/Y36/Y41/Y64/Y128/etc | |

| Diameter/size | 3”/4”/6″LN wafer & 8″under R/D | |

| Tol(±) | <0.20 mm | |

| Thickness | 0.18 ~ 0.5mm or more | |

| Primary Flat | 22mm /32mm /42.5mm /57.5mm | |

| LTV (5mmx5mm) | <1µm | |

| TTV | <3µm | |

| Bow | -30<bow<30 | |

| Warp | <40µm | |

| PLTV(<0.5um) | ≥95%(5mm*5mm) | |

| Orientation Flat | All available | |

| Surface Type | Single Side Polished /Double Sides Polished | |

| Polished side Ra | <0.5nm | |

| Back Side Criteria | General is 0.2-0.5µm or as customized | |

| Edge Criteria | R=0.2mm or Bullnose | |

| Wafer Surface Criteria | Transmissivity | general:5.9×10-11<s<2.0*10-10 at 25℃ |

| Contamination, | None | |

| Particles ¢>0.3 µ m | <= 30 | |

| Scratch , Chipping | None | |

| Defect | No edge cracks, scratches, saw marks, stains | |

| Packaging | Qty/Wafer box | 25pcs per box |

The reduction technique is applied to produce black LN, which neutralizes charges even during instantaneous electric potential. The pyroelectric effect is nearly eliminated, and transmittance significantly reduced. The piezoelectric properties remain unchanged from standard wafers, making black lithium niobate ideal for higher-frequency surface acoustic wave devices.

| Material | Black Lithium Niobate Wafer | |

| Curie Temp | 1142±2.0℃ | |

| Cutting Angle | X/Y/Z/Y36/Y41/Y64/Y128/etc | |

| Diameter/size | 3”/4”/6″ & 8″ LN wafer | |

| Tol(±) | <0.20 mm | |

| Thickness | 0.18 ~ 0.5mm or more | |

| Primary Flat | 22mm /32mm /42.5mm /57.5mm /semi notch | |

| LTV (5mmx5mm) | <1µm | |

| TTV | <3µm | |

| Bow | -30<bow<30 | |

| Warp | <40µm | |

| PLTV(<0.5um) | ≥95%(5mm*5mm) | |

| Surface Type | Single Side Polished /Double Sides Polished | |

| Polished side Ra | <0.5nm | |

| Back Side Criteria | General is 0.2-0.5µm or as customized | |

| Edge Criteria | R=0.2mm or Bullnose | |

| Wafer Surface Criteria | Transmissivity | general:5.9×10-11<s<2.0*10-10 at 25℃ |

| Contamination, | None | |

| Particles ¢>0.3 µ m | <= 30 | |

| Scratch , Chipping | None | |

| Defect | No edge cracks, scratches, saw marks, stains | |

| Packaging | Qty/Wafer box | 25pcs per box |

LiTaO3

| Material | Optical grade LiTaO3 wafers | |

| Curie Temp | 603±2℃ | |

| Cutting Angle | X/Y/Z etc | |

| Diameter/size | 2”/3”/4” LT wafer | |

| Tol(±) | <0.20 mm | |

| Thickness | 0.18 ~ 0.5mm or more | |

| Primary Flat | 16mm/22mm /32mm | |

| TTV | <3µm | |

| Warp | <40µm | |

| Surface Type | Single Side Polished /Double Sides Polished | |

| Polished side Ra | <0.5nm | |

| Back Side Criteria | General is 0.2-0.5µm or as customized | |

| Edge Criteria | R=0.2mm or Bullnose | |

| Optical doped | Zn/MgO etc | |

| Wafer Surface Criteria | Contamination, | None |

| Particles ¢>0.3 µ m | <= 30 | |

| Scratch , Chipping | None | |

| Defect | No edge cracks, scratches, saw marks, stains | |

| Packaging | Qty/Wafer box | 25pcs per box |

| Material | Saw grade LiTaO3 wafers | |

| Curie Temp | 603±2℃ | |

| Cutting Angle | X/Y/Z/X112Y/Y36/Y42/Y48/etc | |

| Diameter/size | 3”/4”/6″ LT wafer | |

| Tol(±) | <0.20 mm | |

| Thickness | 0.18 ~ 0.5mm or more | |

| Primary Flat | 22mm /32mm /42.5mm /57.5mm | |

| LTV (5mmx5mm) | <1µm | |

| TTV | <3µm | |

| Bow | -30<bow<30 | |

| Warp | <40µm | |

| PLTV(<0.5um) | ≥95%(5mm*5mm) | |

| Orientation Flat | All available | |

| Surface Type | Single Side Polished /Double Sides Polished | |

| Polished side Ra | <0.5nm | |

| Back Side Criteria | General is 0.2-0.5µm or as customized | |

| Edge Criteria | R=0.2mm or Bullnose | |

| Wafer Surface Criteria | Transmissivity | general:5.9×10-11<s<2.0*10-10 at 25℃ |

| Contamination, | None | |

| Particles ¢>0.3 µ m | <= 30 | |

| Scratch , Chipping | None | |

| Defect | No edge cracks, scratches, saw marks, stains | |

| Packaging | Qty/Wafer box | 25pcs per box |

An innovative reduction process is applied to produce “black” LT wafers that eliminate pyroelectric discharge, making them ideal for high-frequency SAW applications. During this process, LiTaO₃ crystals undergo chemical reduction in a controlled atmosphere, which preserves key properties such as Curie temperature and piezoelectric characteristics while significantly reducing optical transmittance. These black wafers neutralize electrical charges and offer distinct advantages in applications requiring pyroelectric discharge prevention and high-frequency operation, contributing to improved performance and reliability in advanced SAW devices.

| Material | Black Lithium Niobate Wafer | |

| Curie Temp | 1142±2.0℃ | |

| Cutting Angle | X/Y/Z/Y36/Y41/Y64/Y128/etc | |

| Diameter/size | 3”/4”/6″ & 8″ LN wafer | |

| Tol(±) | <0.20 mm | |

| Thickness | 0.18 ~ 0.5mm or more | |

| Primary Flat | 22mm /32mm /42.5mm /57.5mm /semi notch | |

| LTV (5mmx5mm) | <1µm | |

| TTV | <3µm | |

| Bow | -30<bow<30 | |

| Warp | <40µm | |

| PLTV(<0.5um) | ≥95%(5mm*5mm) | |

| Surface Type | Single Side Polished /Double Sides Polished | |

| Polished side Ra | <0.5nm | |

| Back Side Criteria | General is 0.2-0.5µm or as customized | |

| Edge Criteria | R=0.2mm or Bullnose | |

| Wafer Surface Criteria | Transmissivity | general:5.9×10-11<s<2.0*10-10 at 25℃ |

| Contamination, | None | |

| Particles ¢>0.3 µ m | <= 30 | |

| Scratch , Chipping | None | |

| Defect | No edge cracks, scratches, saw marks, stains | |

| Packaging | Qty/Wafer box | 25pcs per box |

Specifications

LiNbO3

| Material | Optical grade LiNbO3 wafers | |

| Curie Temp | 1142±2.0℃ | |

| Cutting Angle | X/Y/Z etc | |

| Diameter/size | 2”/3”/4” | |

| Tol(±) | <0.20 mm | |

| Thickness | 0.18 ~ 0.5mm or more | |

| Primary Flat | 16mm/22mm /32mm | |

| TTV | <3µm | |

| Bow | -30<bow<30 | |

| Warp | <40µm | |

| Orientation Flat | All available | |

| Surface Type | Single Side Polished /Double Sides Polished | |

| Polished side Ra | <0.5nm | |

| S/D | 20/10 | |

| Edge Criteria | R=0.2mm or Bullnose | |

| Optical doped | Fe/Zn/MgO etc | |

| Wafer Surface Criteria | Refractive index | No=2.2878/Ne=2.2033 @632nm wavelength |

| Contamination, | None | |

| Particles ¢>0.3 µ m | <= 30 | |

| Scratch , Chipping | None | |

| Defect | No edge cracks, scratches, saw marks, stains | |

| Packaging | Qty/Wafer box | 25pcs per box |

| Material | SAW grade LiNbO3 wafers | |

| Curie Temp | 1142±2.0℃ | |

| Cutting Angle | X/Y/Z/Y36/Y41/Y64/Y128/etc | |

| Diameter/size | 3”/4”/6″LN wafer & 8″under R/D | |

| Tol(±) | <0.20 mm | |

| Thickness | 0.18 ~ 0.5mm or more | |

| Primary Flat | 22mm /32mm /42.5mm /57.5mm | |

| LTV (5mmx5mm) | <1µm | |

| TTV | <3µm | |

| Bow | -30<bow<30 | |

| Warp | <40µm | |

| PLTV(<0.5um) | ≥95%(5mm*5mm) | |

| Orientation Flat | All available | |

| Surface Type | Single Side Polished /Double Sides Polished | |

| Polished side Ra | <0.5nm | |

| Back Side Criteria | General is 0.2-0.5µm or as customized | |

| Edge Criteria | R=0.2mm or Bullnose | |

| Wafer Surface Criteria | Transmissivity | general:5.9×10-11<s<2.0*10-10 at 25℃ |

| Contamination, | None | |

| Particles ¢>0.3 µ m | <= 30 | |

| Scratch , Chipping | None | |

| Defect | No edge cracks, scratches, saw marks, stains | |

| Packaging | Qty/Wafer box | 25pcs per box |

The reduction technique is applied to produce black LN, which neutralizes charges even during instantaneous electric potential. The pyroelectric effect is nearly eliminated, and transmittance significantly reduced. The piezoelectric properties remain unchanged from standard wafers, making black lithium niobate ideal for higher-frequency surface acoustic wave devices.

| Material | Black Lithium Niobate Wafer | |

| Curie Temp | 1142±2.0℃ | |

| Cutting Angle | X/Y/Z/Y36/Y41/Y64/Y128/etc | |

| Diameter/size | 3”/4”/6″ & 8″ LN wafer | |

| Tol(±) | <0.20 mm | |

| Thickness | 0.18 ~ 0.5mm or more | |

| Primary Flat | 22mm /32mm /42.5mm /57.5mm /semi notch | |

| LTV (5mmx5mm) | <1µm | |

| TTV | <3µm | |

| Bow | -30<bow<30 | |

| Warp | <40µm | |

| PLTV(<0.5um) | ≥95%(5mm*5mm) | |

| Surface Type | Single Side Polished /Double Sides Polished | |

| Polished side Ra | <0.5nm | |

| Back Side Criteria | General is 0.2-0.5µm or as customized | |

| Edge Criteria | R=0.2mm or Bullnose | |

| Wafer Surface Criteria | Transmissivity | general:5.9×10-11<s<2.0*10-10 at 25℃ |

| Contamination, | None | |

| Particles ¢>0.3 µ m | <= 30 | |

| Scratch , Chipping | None | |

| Defect | No edge cracks, scratches, saw marks, stains | |

| Packaging | Qty/Wafer box | 25pcs per box |

LiTaO3

| Material | Optical grade LiTaO3 wafers | |

| Curie Temp | 603±2℃ | |

| Cutting Angle | X/Y/Z etc | |

| Diameter/size | 2”/3”/4” LT wafer | |

| Tol(±) | <0.20 mm | |

| Thickness | 0.18 ~ 0.5mm or more | |

| Primary Flat | 16mm/22mm /32mm | |

| TTV | <3µm | |

| Warp | <40µm | |

| Surface Type | Single Side Polished /Double Sides Polished | |

| Polished side Ra | <0.5nm | |

| Back Side Criteria | General is 0.2-0.5µm or as customized | |

| Edge Criteria | R=0.2mm or Bullnose | |

| Optical doped | Zn/MgO etc | |

| Wafer Surface Criteria | Contamination, | None |

| Particles ¢>0.3 µ m | <= 30 | |

| Scratch , Chipping | None | |

| Defect | No edge cracks, scratches, saw marks, stains | |

| Packaging | Qty/Wafer box | 25pcs per box |

| Material | Saw grade LiTaO3 wafers | |

| Curie Temp | 603±2℃ | |

| Cutting Angle | X/Y/Z/X112Y/Y36/Y42/Y48/etc | |

| Diameter/size | 3”/4”/6″ LT wafer | |

| Tol(±) | <0.20 mm | |

| Thickness | 0.18 ~ 0.5mm or more | |

| Primary Flat | 22mm /32mm /42.5mm /57.5mm | |

| LTV (5mmx5mm) | <1µm | |

| TTV | <3µm | |

| Bow | -30<bow<30 | |

| Warp | <40µm | |

| PLTV(<0.5um) | ≥95%(5mm*5mm) | |

| Orientation Flat | All available | |

| Surface Type | Single Side Polished /Double Sides Polished | |

| Polished side Ra | <0.5nm | |

| Back Side Criteria | General is 0.2-0.5µm or as customized | |

| Edge Criteria | R=0.2mm or Bullnose | |

| Wafer Surface Criteria | Transmissivity | general:5.9×10-11<s<2.0*10-10 at 25℃ |

| Contamination, | None | |

| Particles ¢>0.3 µ m | <= 30 | |

| Scratch , Chipping | None | |

| Defect | No edge cracks, scratches, saw marks, stains | |

| Packaging | Qty/Wafer box | 25pcs per box |

An innovative reduction process is applied to produce “black” LT wafers that eliminate pyroelectric discharge, making them ideal for high-frequency SAW applications. During this process, LiTaO₃ crystals undergo chemical reduction in a controlled atmosphere, which preserves key properties such as Curie temperature and piezoelectric characteristics while significantly reducing optical transmittance. These black wafers neutralize electrical charges and offer distinct advantages in applications requiring pyroelectric discharge prevention and high-frequency operation, contributing to improved performance and reliability in advanced SAW devices.

| Material | Black Lithium Niobate Wafer | |

| Curie Temp | 1142±2.0℃ | |

| Cutting Angle | X/Y/Z/Y36/Y41/Y64/Y128/etc | |

| Diameter/size | 3”/4”/6″ & 8″ LN wafer | |

| Tol(±) | <0.20 mm | |

| Thickness | 0.18 ~ 0.5mm or more | |

| Primary Flat | 22mm /32mm /42.5mm /57.5mm /semi notch | |

| LTV (5mmx5mm) | <1µm | |

| TTV | <3µm | |

| Bow | -30<bow<30 | |

| Warp | <40µm | |

| PLTV(<0.5um) | ≥95%(5mm*5mm) | |

| Surface Type | Single Side Polished /Double Sides Polished | |

| Polished side Ra | <0.5nm | |

| Back Side Criteria | General is 0.2-0.5µm or as customized | |

| Edge Criteria | R=0.2mm or Bullnose | |

| Wafer Surface Criteria | Transmissivity | general:5.9×10-11<s<2.0*10-10 at 25℃ |

| Contamination, | None | |

| Particles ¢>0.3 µ m | <= 30 | |

| Scratch , Chipping | None | |

| Defect | No edge cracks, scratches, saw marks, stains | |

| Packaging | Qty/Wafer box | 25pcs per box |