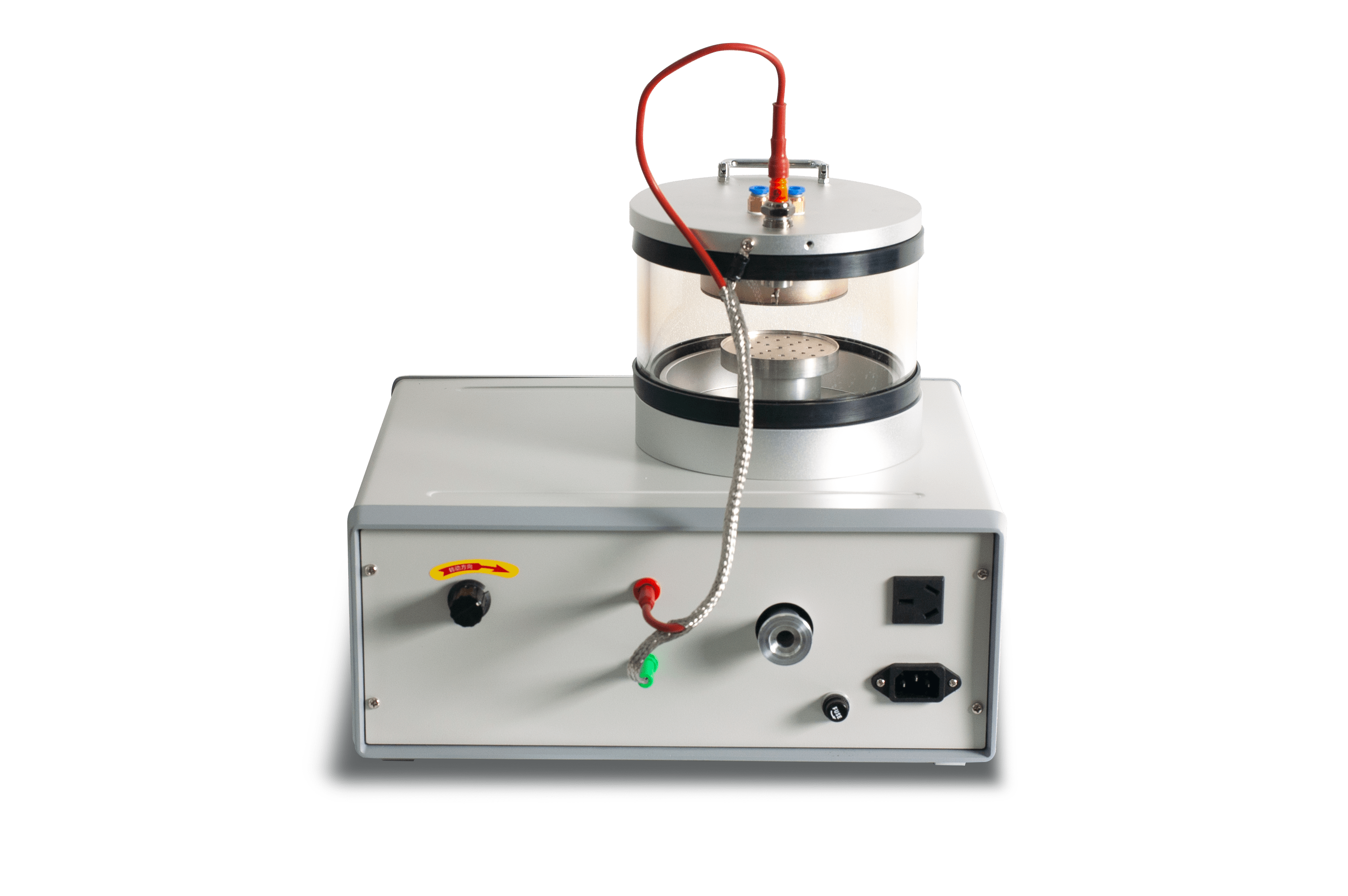

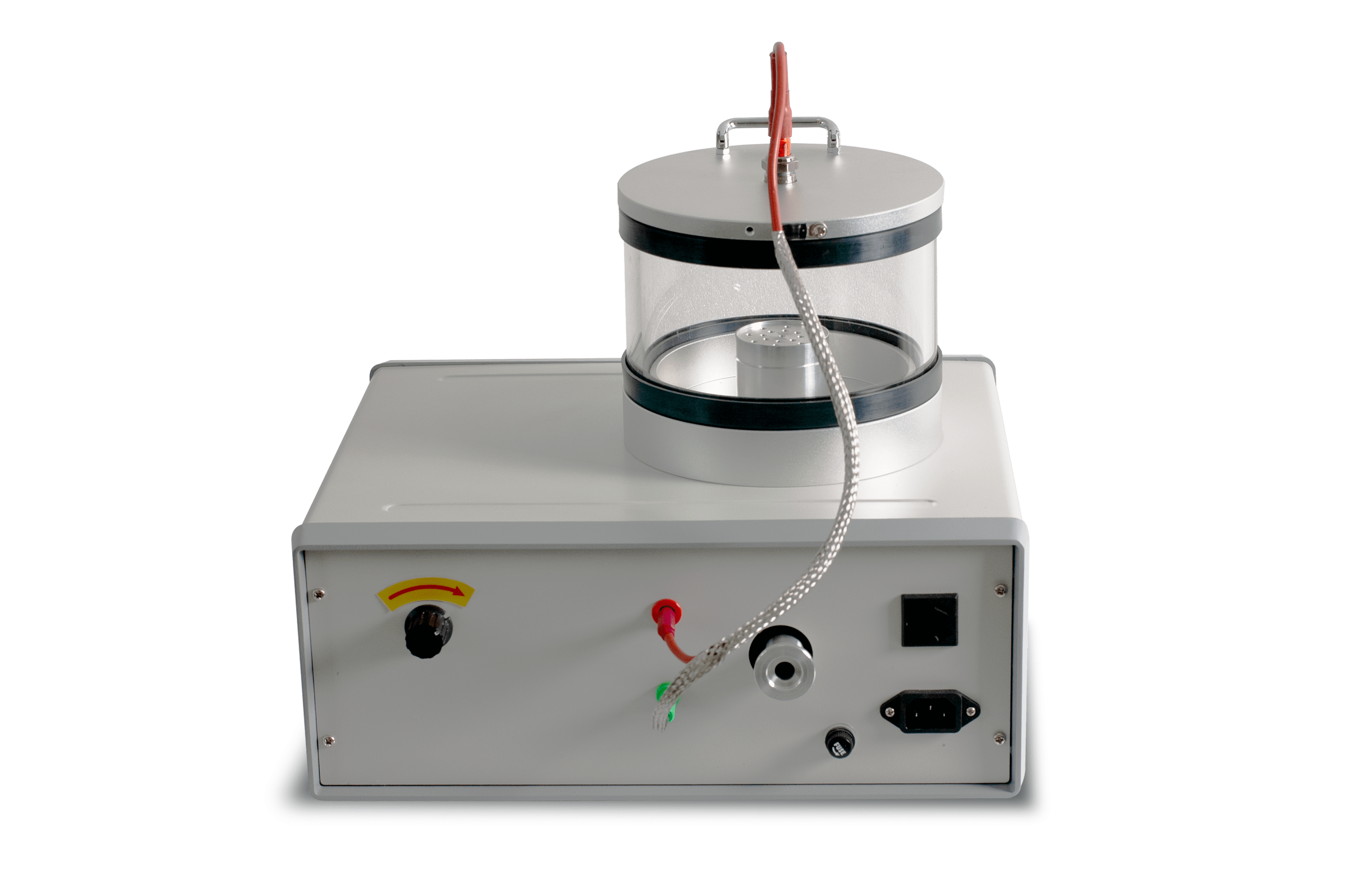

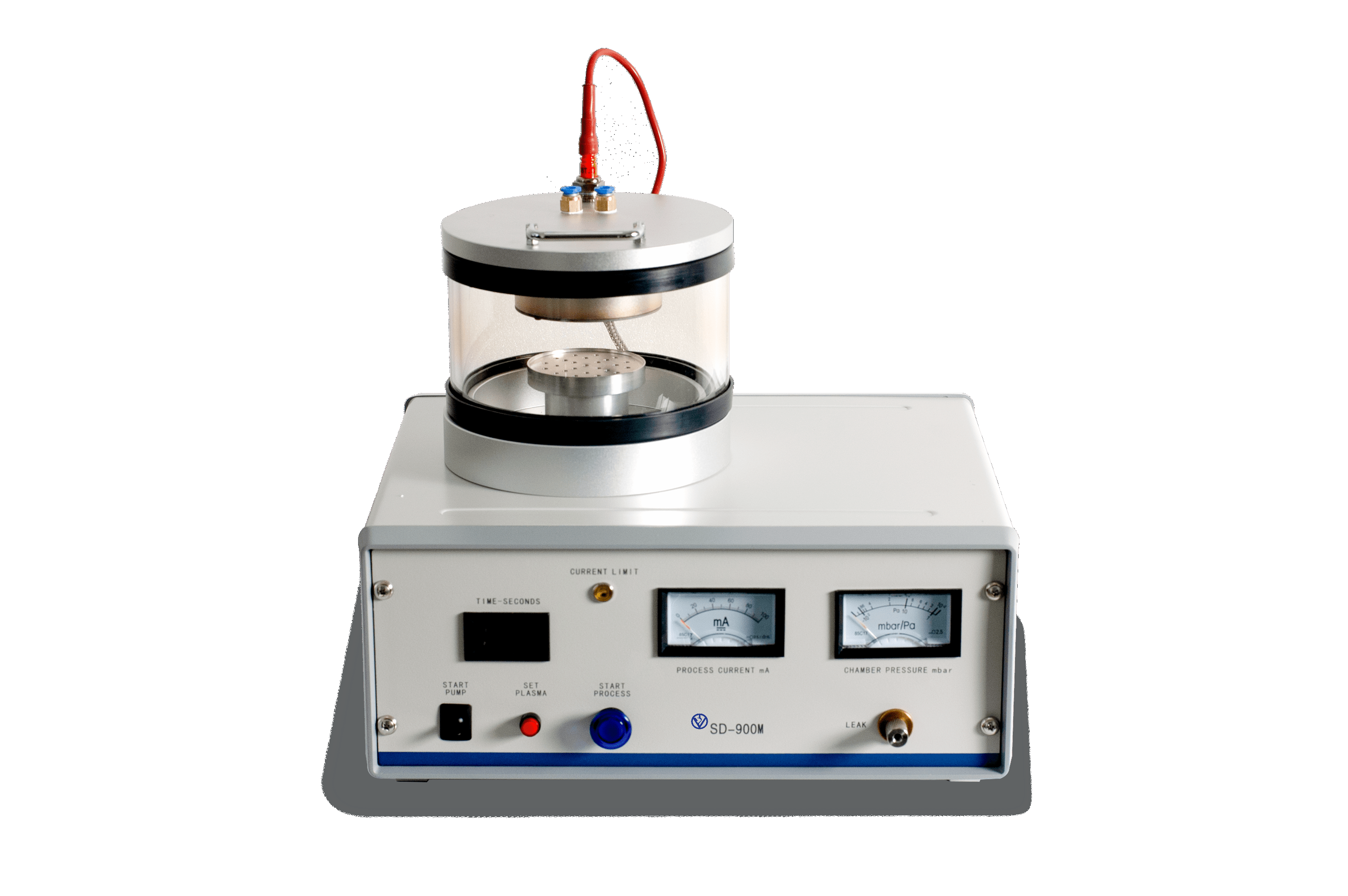

SD-900M

SD-900M is ideal for heat-sensitive sample preparation. Magnetron sputtering is highly advantageous for depositing precise thin films on heat-sensitive substrates, as it traps plasma near the target, minimizing substrate damage from heat and ion impact. It is widely used to coat non-conductive SEM samples with gold for better imaging. It is also excellent for surface treatment. It can quickly reach its working vacuum pressure within 5 minutes with a proper vacuum pump. It’s user friendly and easy to operate. The package includes a vacuum pump while a chiller is optional. Thickness monitor is available as an option.