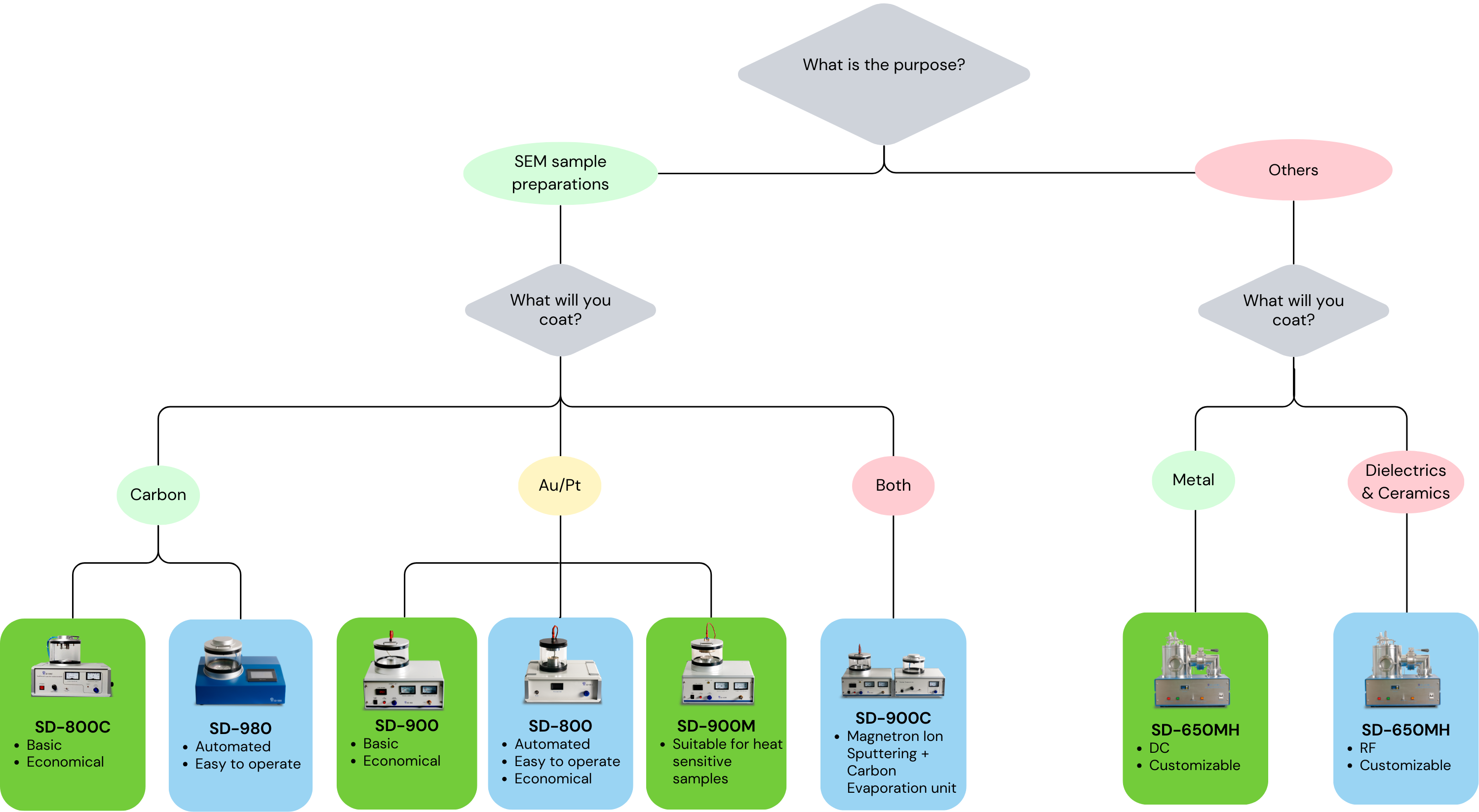

Seven Models to Meet Your Needs

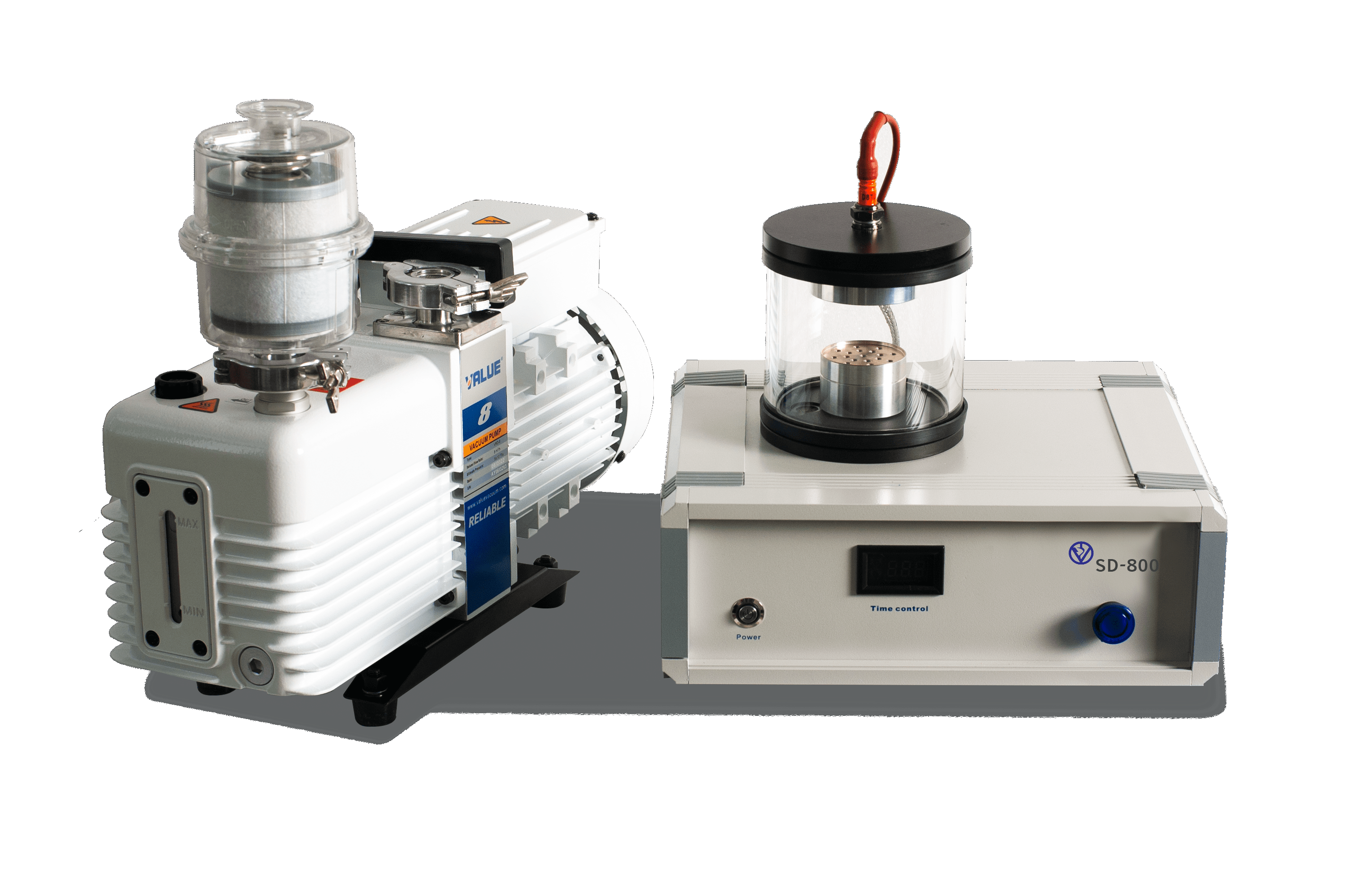

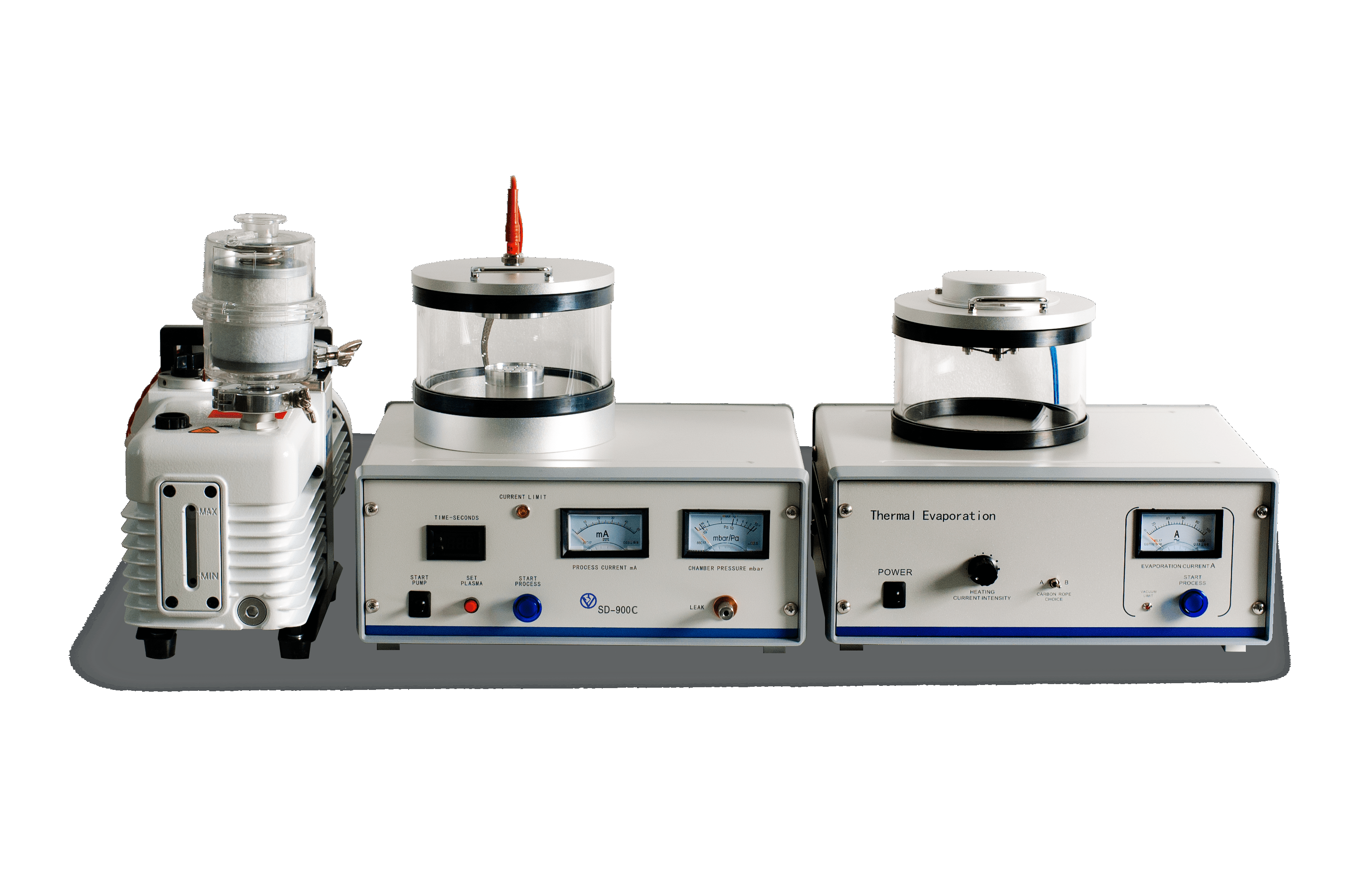

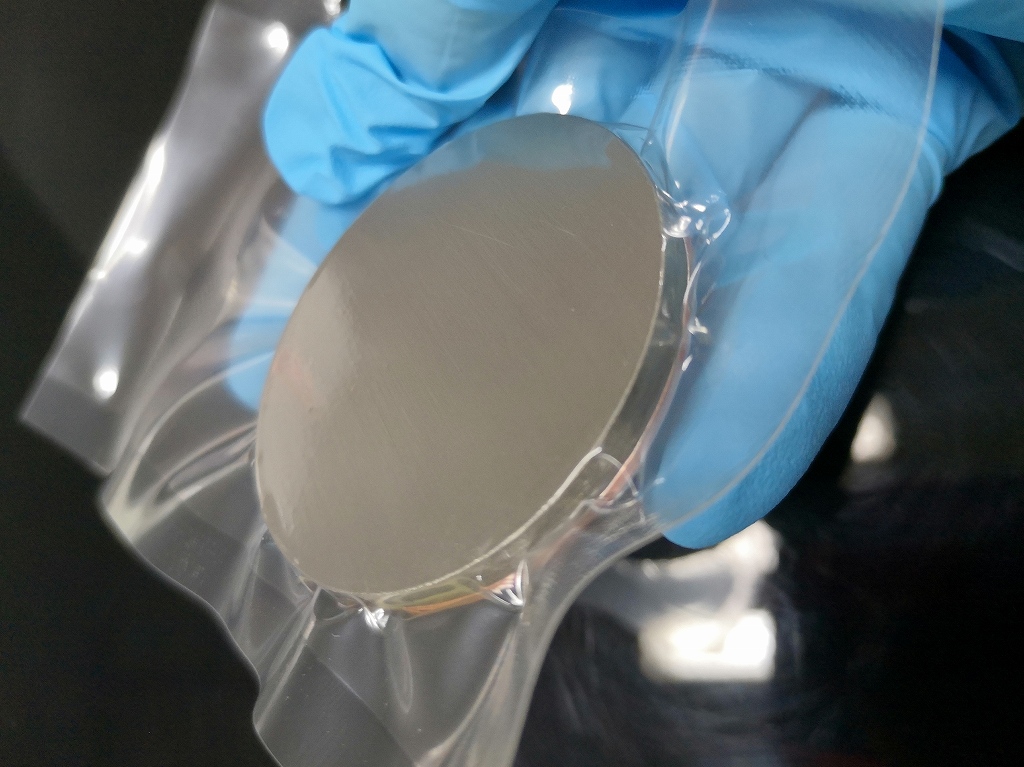

We offer 7 models of PVD coaters, including 4 sputter coaters, 2 evaporation coaters, and 1 combined (sputter + evaporation) system. Our versatile lineup caters to the specific needs of research institutions and universities, delivering cost-competitive solutions for SEM sample preparation and thin film deposition for various purposes.