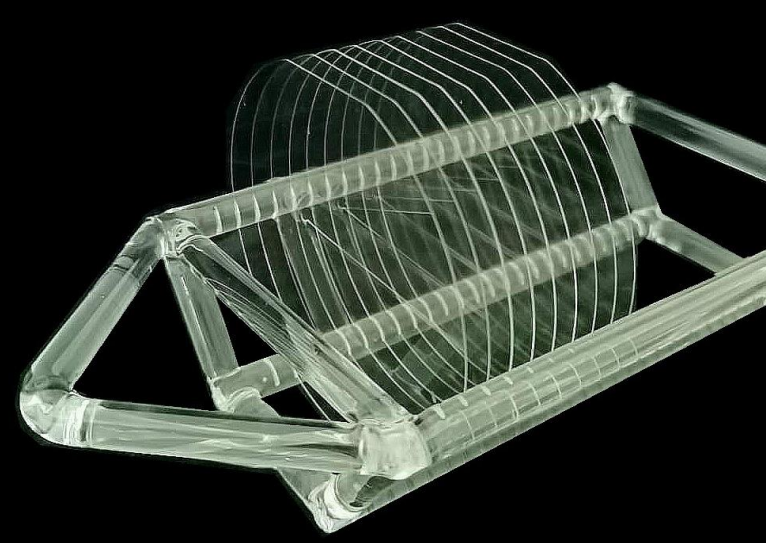

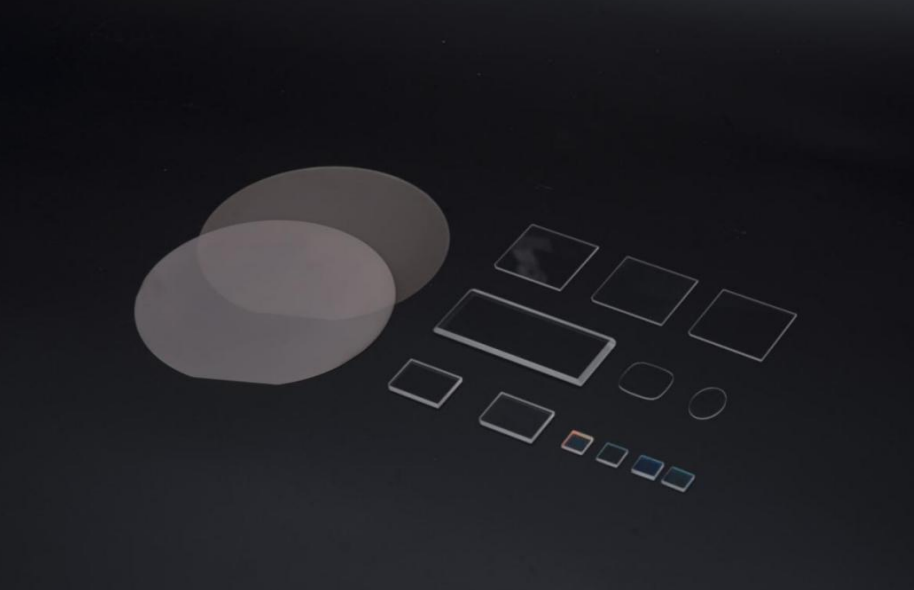

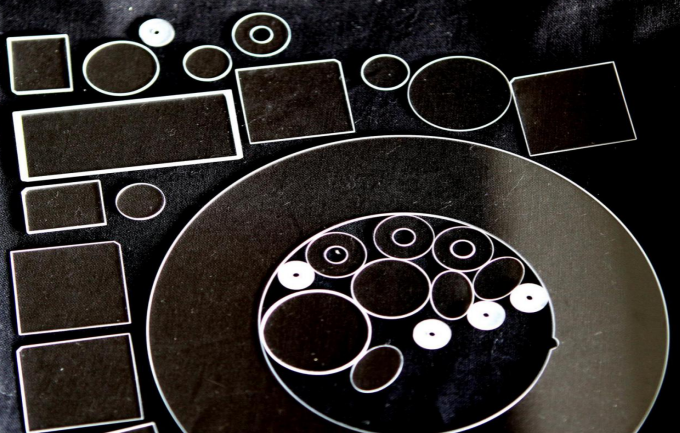

Fused Silica, Glass wafers

Fused quartz and fused silica wafers are essential for semiconductor and optical applications due to their high purity, thermal stability, and electrical insulation properties. Fused quartz is ideal for high-temperature processes like chemical vapor deposition (CVD) and epitaxial growth, and its transparency in UV and IR spectra makes it suitable for photolithography and laser applications. Fused silica, valued for its heat resistance and broad transmission range, is available in UV and IR grades. UV grade fused silica (JGS1, Corning 7980, SK1300) has excellent purity and optical properties, ideal for deep ultraviolet (DUV) applications, while IR grade fused silica (JGS3, Corning 7979, SK1310) is optimized for infrared transmission, with low hydroxyl content leading minimal absorption in the IR region. Our products meet the precision needs of both semiconductor and optical industries, supporting applications like photolithography, laser optics, and high-precision optical components.

For inquiry, please give us the following information:

- Size with tolerance (Diameter / Thickness )

- Material (JGS1, JGS2, Borofloat 33, Coring, B270, BK7 ,Soda lime, etc.

- Quantity

General specifications

| unit | 4″ | 6″ | 8″ | 10″ | 12” | |

| Diameter/size(or square) | mm | 100 | 150 | 200 | 250 | 300 |

| Tolerance (±) | mm | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| Thickness | mm | 0.10 or more | 0.30 or more | 0.40 or more | 0.50 or more | 0.50 or more |

| Primary reference flat | mm | 32.5 | 57.5 | Semi-notch | Semi-notch | Semi-notch |

| LTV (5mmx5mm) | µm | < 0.5 | < 0.5 | < 0.5 | < 0.5 | < 0.5 |

| TTV | µm | < 2 | < 3 | <3 | <5 | <5 |

| Bow | µm | ±20 | ±30 | ±40 | ±40 | ±40 |

| Warp | µm | ≤ 30 | ≤ 40 | ≤ 50 | ≤ 50 | ≤ 50 |

| PLTV(5mm*5mm)<0.4um | % | ≥95% | ≥95% | ≥95% | ≥95% | ≥95% |

| Edge Rounding | mm | Compliant with SEMI M1.2 Standard/refer to IEC62276 | ||||

| Surface Type | Single Side Polished /Double Sides Polished | |||||

| Polished side Ra | nm | ≤1 | ||||

| Back Side Criteria | µm | general 0.2-0.7 or customized | ||||

General specifications

| unit | 4″ | 6″ | 8″ | 10″ | 12” | |

| Diameter/size(or square) | mm | 100 | 150 | 200 | 250 | 300 |

| Tolerance (±) | mm | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| Thickness | mm | 0.10~ | 0.30~ | 0.40~ | 0.50~ | 0.50~ |

| Primary reference flat | mm | 32.5 | 57.5 | Semi-

notch |

Semi-

notch |

Semi-

notch |

| LTV (5mmx5mm) | µm | < 0.5 | < 0.5 | < 0.5 | < 0.5 | < 0.5 |

| TTV | µm | < 2 | < 3 | <3 | <5 | <5 |

| Bow | µm | ±20 | ±30 | ±40 | ±40 | ±40 |

| Warp | µm | ≤ 30 | ≤ 40 | ≤ 50 | ≤ 50 | ≤ 50 |

| PLTV(5mm*5mm)<0.4um | % | ≥95% | ≥95% | ≥95% | ≥95% | ≥95% |

| Edge Rounding | mm | Compliant with SEMI M1.2 Standard/refer to IEC62276 | ||||

| Surface Type | Single Side Polished /Double Sides Polished | |||||

| Polished side Ra | nm | ≤1 | ||||

| Back Side Criteria | µm | general 0.2-0.7 or customized | ||||